Industrial assembly lines require high precision and repeatability to maximize quality and output. Linear actuators and automated Electric Torque Screwdrivers are increasingly being integrated into these systems to improve performance. In this guide, we’ll explore key considerations for building a precision assembly system using these technologies.

Defining Assembly System Requirements

The first step is understanding your specific assembly needs. Important requirements to consider include:

- Target cycle time per assembly

- Required precision and tolerances

- Nature of parts being handled and joined

- Production volume expectations

- Available footprint for the system

- Budget constraints

Thoroughly analyzing your application requirements will guide selection of appropriate equipment.

Incorporating Linear Actuation

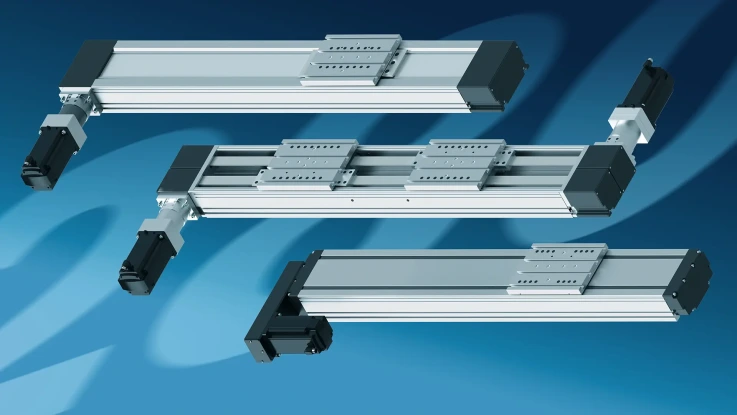

Linear actuators provide straight-line motion to position and manipulate parts. Compared to rotary counterparts, they excel in providing high precision and repeatability critical for assembly systems.

Various linear actuator designs exist using different drive mechanisms—such as belt, screw, or magnetic—each with unique performance trade-offs. We’ll focus on discussing ball screw actuators offering the best precision.

Guiding benefits of linear actuators:

- Position parts within microns accuracy repeatedly

- Generate substantial linear forces for manipulating parts

- Integrate feedback sensors for closed-loop control

- Facilitate flexible positioning of parts

Multi-axis gantry styles, rod-type, or guided styles can be implemented as needed.

Automating Fastening with Torque Tools

Precision fastening is critical for robust, reliable assemblies. However, manual torqueing of fasteners has variations leading to inconsistencies.

Automated torque tools overcome this through electric or pneumatic capabilities to accurately meet target torque specifications repeatedly. They also facilitate data reporting for analysis.

Modular torque tool types allow mounting inline or at angles to access fasteners in tight spaces. Right angle styles, screwdrivers, nutrunners, drills and more cover various needs.

Let’s discuss some key points on torque tool benefits:

- Apply programmed torque values within ±3% accuracy

- Built-in transducers provide torque-angle signatures

- Torque graphs track performance and can integrate with SPC

- Flexible tool changing for multi-size fasteners

- Optional process controllers simplify integration

This instrumentation empowers gathering intelligence to optimize the join process.

Incorporating Robotic Flexibility

For multiplying production output, flexibility, or ergonomic safety, industrial robots present strong benefits for assembly systems. Cartesian, SCARA, 6-axis and custom robots each serve distinct applications.

Robots can handle higher payloads, extend reach to multiple stations, and allow easy reconfiguration. When equipped with force-torque sensors and machine vision, even greater manufacturing capabilities are possible.

Notable strengths robots add to assembly systems:

- Adaptability for future product changes

- Consistent, non-tiring performance

- Multi-tasking of loading, gluing, driving fasteners

- Scalability to add processes over time

- Safer operations isolating people

With programmable flexibility, robotic systems enhance ROI through maximizing future utilization over longer equipment lifetimes.

Tying Together Control & Monitoring

Underpinning hardware with capable software, control interfaces & data monitoring empowers an intelligent, connected assembly platform.

Industrial PLCs or PACs form the controller backbone handling discrete/analog I/O, motion control and HMI interfaces. Modern equipment now uses EtherCAT or Sercos digital comms for high-speed, deterministic performance & diagnostics not possible previously with analog/serial connections from components.

Supplementing hardware with custom GUI interfaces on industrial PCs or tablets allows specialized control & insights for each application. Dashboards with key performance analytics related to individual processes, or across the assembly system enable identifying optimization areas.

This software aspect aims to simplify the customer machine integration experience through:

- Assisted machine configuration wizards

- Pre-built motion profiles tailored to the mechanics

- Changeover assistants guiding fast product model change

- Maintenance tracking and predictive notifications

The collective impact makes the automated assembly platform easier to use, flexible for future products, while maximizing uptime.

Why Choose Flexible Assembly Systems?

Automation technology aims to amplify human abilities, allowing us to achieve more together. By combining custom mechanical engineering with versatile electromechanical modules and intuitive software tools, Flexible Assembly Systems strives to make next-gen assembly machinery accessible to all manufacturers.

We thrive on supporting customers tackle precision assembly challenges across an array of industries by asking questions first to grasp application goals. Our mission focuses on configuring adaptable, high quality solutions matching budget & technical needs rather than over-engineering. And we pride ourselves on transparent, metric-driven relationships assessing project success based on business results achieved post-deployment.

Want to inline instrumentation driving actionable insights? Our connectivity tools fuse siloed data into visual production performance metrics. Need consistent quality but have fast changeovers between product variations? Our modular fixturing and change part assist wizards rapidly adapt in minutes. Have concerns over finding skilled staff for operating advanced machinery? Our intuitive software aims to simplify interactions through self-guided interfaces.

In an increasingly complex manufacturing world, Flexible Assembly Systems aspires to thoughtfully leverage technology for empowering your team’s craftsmanship to shine. We invite you to start a conversation around what thoughtful automation could unlock for your production environment.