In the world of traditional craftsmanship and modern industrial processes, few elements bridge both realms as effectively as zuschneidfelle. Often overlooked, this term carries deep significance in industries such as leather crafting, fur preparation, garment manufacturing, and artisan work. This comprehensive article explores zuschneidfelle—what it is, its origins, uses, evolving relevance, and future in sustainable production. We dive deep into the subject with a unique lens, helping manufacturers, designers, and curious readers understand the full landscape of this age-old yet evolving practice.

What Does Zuschneidfelle Mean?

The word zuschneidfelle comes from the German language and literally translates to “cutting skins” or “skins for cutting.” It refers to animal skins—typically leather, fur, or hides—that are prepared and selected specifically for cutting in the process of manufacturing goods. These skins are usually pre-treated and measured for optimal use.

Unlike generic leather or pelts, zuschneidfelle are curated for maximum material efficiency and precision. This makes them highly valuable in workshops and factories where uniformity, quality, and sustainable use of animal products are critical.

A Historical Overview: The Craft Behind Zuschneidfelle

Ancient Roots in Leatherwork

For thousands of years, humans have been using animal hides for shelter, clothing, tools, and trade. The process of tanning hides into leather is one of the oldest forms of craftsmanship, dating back to ancient Mesopotamia and Egypt. Zuschneidfelle evolved as artisans began recognizing the value of selecting specific hides for precise cutting tasks.

In medieval Europe, the leather and fur trades were heavily regulated by guilds. Craftsmen were trained for years before being entrusted with selecting zuschneidfelle, a task that required knowledge of animal anatomy, hide quality, stretch direction, and optimal usage.

Zuschneidfelle in Modern Manufacturing

Today, zuschneidfelle are used in industries that produce luxury leather goods, footwear, furniture, automobile interiors, and garments. The process remains a blend of art and science, requiring an understanding of leather behavior, cutting technology, and sustainable use of raw materials.

Key Industries Using Zuschneidfelle

- Fashion and Apparel: High-end fashion brands depend on premium zuschneidfelle to create bags, jackets, shoes, and accessories. The right cut can make the difference between a luxury product and a defective one.

- Automotive Interiors: Car manufacturers, especially in premium models, use zuschneidfelle to upholster seats, dashboards, and panels, ensuring consistency and durability.

- Upholstery and Furniture: Sofas, chairs, and custom furnishings require large, clean-cut panels from zuschneidfelle to maintain aesthetic appeal and performance.

- Tool and Gear Manufacturing: In specialized equipment, such as belts, holsters, and tool wraps, precision-cut leather from zuschneidfelle is essential for durability and ergonomics.

The Art of Selecting Zuschneidfelle

Master cutters, or “Zuscheider” in German, use trained eyes and tactile sense to evaluate a skin’s readiness for cutting. Here are some critical factors in evaluating a skin:

- Grain Quality: The surface must be smooth and blemish-free for fashion items.

- Stretch Direction: Leather stretches more along certain axes; cutters must align patterns accordingly.

- Thickness Uniformity: For shoes or upholstery, consistent thickness is vital.

- Tanning Method: Chrome-tanned and vegetable-tanned skins behave differently under tools.

High-end workshops even employ light tables and laser measurement tools to analyze each zuschneidfelle for imperfections and yield estimation.

Technology and Zuschneidfelle: Automation Meets Tradition

Though traditionally manual, the cutting process for zuschneidfelle has embraced modern technologies:

- CAD (Computer-Aided Design): Pattern placement software helps maximize yield from each skin.

- Laser and Waterjet Cutting: These allow precise cuts, especially useful in mass production while reducing waste.

- Digital Scanning: Skins are scanned for thickness and blemishes before being fed into cutting algorithms.

Still, human oversight remains essential—no machine can yet fully replicate the instinct and sensitivity of a trained cutter analyzing a piece of natural hide.

Sustainability and Ethics: The Modern Face of Zuschneidfelle

In today’s eco-conscious market, the sourcing and processing of animal products are under close scrutiny. Here’s how zuschneidfelle fit into the sustainable narrative:

- Byproduct Philosophy: Ethical leather production views hides as byproducts of the meat industry, reducing waste.

- Sustainable Tanning: Modern tanneries use vegetable-based agents and closed-loop water systems.

- Traceability: Many manufacturers now demand traceable zuschneidfelle, linking each piece to its farm and tanning process.

Moreover, demand for eco-leather (tanned without heavy metals) and biodegradable treatments has increased. The leather industry is adapting, and zuschneidfelle are at the heart of this transformation.

The Rise of Synthetic Zuschneidfelle Alternatives

With vegan fashion on the rise, synthetic and plant-based alternatives to traditional leather are making waves. While not technically zuschneidfelle, some brands use the term figuratively when referencing high-quality synthetic sheets cut similarly.

Popular alternatives include:

- Mycelium Leather (from mushroom roots)

- Pineapple Fiber (Piñatex)

- Recycled PU and PVC-Based Materials

- Lab-Grown Collagen Leathers

While these materials lack some tactile qualities of real leather, they are gaining ground in fashion and design sectors committed to cruelty-free options.

How to Source High-Quality Zuschneidfelle

Whether you’re an artisan cobbler or a large-scale manufacturer, sourcing the right zuschneidfelle is crucial. Here are the best practices:

- Choose Certified Suppliers: Look for suppliers with certifications in traceability, sustainable practices, and animal welfare.

- Request Samples: Never order in bulk without evaluating texture, flexibility, and response to cutting.

- Inquire About Processing: Understand the tanning method used—this affects everything from workability to environmental impact.

- Buy in Accordance with Pattern Needs: Match hide size and grain to your cutting patterns to minimize waste.

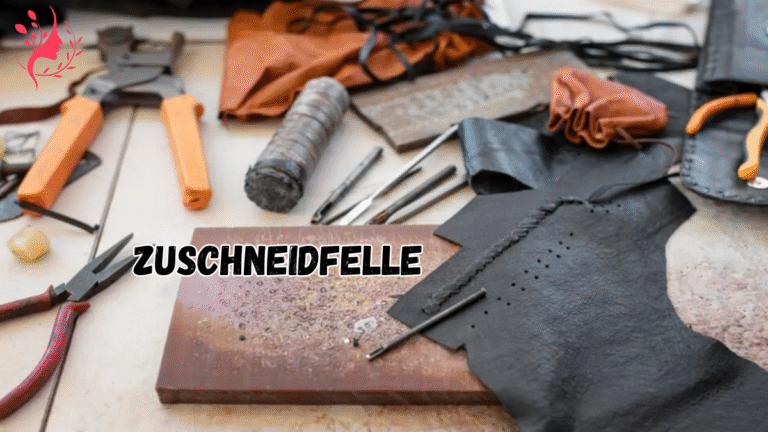

Craftsmanship in Practice: A Glimpse Inside a Zuschneidfelle Workshop

In a modern-day workshop, you’ll find a blend of tradition and innovation. Craftsmen lay out skins under natural light, chalk out patterns based on the best yield orientation, and trim manually or using semi-automated tools.

Each skin is treated as unique—what might be a flaw in one skin can be a feature in another. Zuschneidfelle aren’t just materials; they are canvases, each with its own history and destiny.

Final Thoughts: The Enduring Value of Zuschneidfelle

Zuschneidfelle embody a quiet but vital chapter of human craftsmanship and industrial evolution. Whether you’re a high-end fashion label, a leather goods startup, or a sustainability-minded artisan, understanding and using zuschneidfelle unlocks opportunities in quality, aesthetics, and ethical production.

Their story is one of tradition evolving alongside innovation. With continued emphasis on sustainable sourcing, technology integration, and mindful consumption, zuschneidfelle remain a keystone of premium manufacturing.

FAQs About Zuschneidfelle

Q1: Are zuschneidfelle always made from real leather?

A: Traditionally, yes. But the term is now occasionally applied to high-end synthetic or bio-based materials mimicking real hides.

Q2: How are zuschneidfelle priced?

A: Based on origin, tanning method, grain quality, thickness, and usable area. Premium hides can fetch high prices.

Q3: Can beginners use zuschneidfelle in home workshops?

A: Absolutely. Many suppliers offer pre-cut zuschneidfelle for hobbyists, complete with instructions and pattern guides.

For more information visite the website